VC Velocity Control Severe Service Trims

Anti Cavitation Velocity Control – Liquid Applications

The VC Trim is used for liquid, applications where the pressure drop is high enough to cause severe cavitation and the energy being dissipated is significant enough to cause substantial damage to standard trims and pipe work.

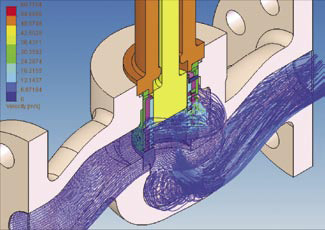

The multi stage design of the VC Trim eliminates cavitation and ensures the trim exit velocity is maintained at acceptable levels. As the liquid moves through the passages in the VC Trim the energy is dissipated through sharp direction changes, friction and turbulence.

The total pressure drop is distributed over a series of stages and cavitation is prevented from occurring by ensuring that the internal fluid pressure does not fall below the vapor pressure at any stage.

The design of the VC Trim provides sufficient number of discrete pressure reduction stages to maintain the trim exit velocity below 23 m/sec (75 ft/sec).

Noise Attenuation Velocity Control – Gas Applications

The VC trim is used for vapour and gas applications where the pressure drop is high enough to cause high noise levels and the energy being dissipated is significant enough to cause substantial damage to standard trims and pipe work.

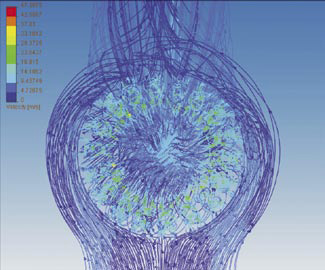

The VC Trim divides the flow into many small streams and utilizes expansion and contraction, friction and changes in flow direction to convert the high upstream potential energy directly into heat. The multi stage design of the VC trim controls the Velocity Head through each stage of the trim at levels that do not create high noise or control valve induced vibration.

The VC Trim is also a technically superior and cost effective alternative to conventional noise abating devices (ie silencers) in gas and vapor atmospheric vent applications. The VC Vent Stack effectively performs the duty of both the pressure let down valve and the atmospheric silencer, eliminating the need for the atmospheric vent silencer altogether. The VC Vent Stack is installed downstream of the valve, reducing the required size of the valve body and as a silencer is not required the total weight of the “system” is greatly reduced. This provides significant savings to otherwise expensive construction and formwork required to install large and heavy silencers.

VC Trim Design

MASCOT utilises computer aided design and state of the art flow modeling software to accurately calculate the process velocity at all points within the VC trim and valve body.