Spring Cylinder Linear Actuator

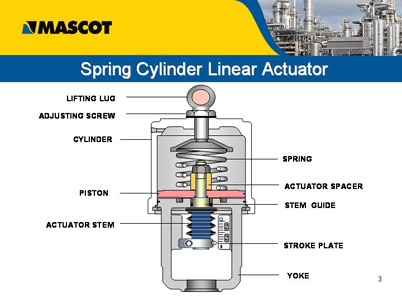

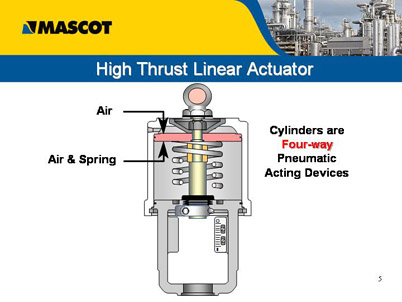

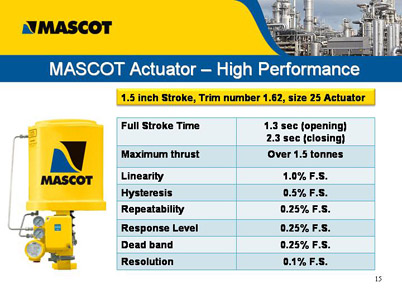

The MASCOT spring cylinder linear actuator is a powerful, high-performance pneumatic actuator that provides positive throttling or on-off operation for automatic control valves. The positioner and most sized cylinders are designed for supply pressures up to 150 psi, making very high thrusts attainable in a compact unit.

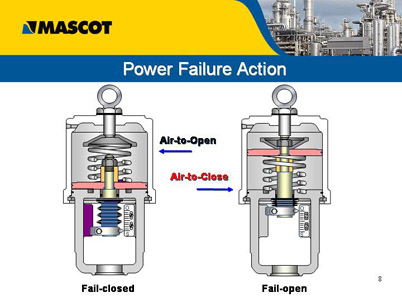

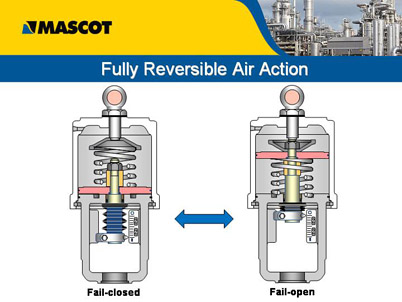

This actuator is fully field reversible for air-to-open or air-to-close action without additional parts; a spring provides fail-safe operation. The positioner supplies air to both sides of the piston, providing exceptionally stiff, precise movement together with very high frequency response.

Spring Cylinder Linear Actuator Features

High thrust capability

150 psi (10.3 Bar) operating pressure allows substantially higher thrust capabilities than comparable diaphragm actuators. Higher thrust allows tighter valve shutoff.

High frequency

Double-acting configuration responds quickly to signal changes. response

Compact and lightweight

Spring cylinder linear actuators are substantially lighter and more compact than comparable linear diaphragm actuators, for easier installation and maintenance.

Wide range of sizes

Standard actuator sizes 25, 50 and 100 will handle thrust requirements for over 95 percent of process applications. Larger sizes up through size 600 are available for special applications.

Fewer parts

Spring cylinder linear actuators have 1 /3 fewer parts than diaphragm linear actuators. Wear parts cost 1 /10 of those for diaphragms, and less inventory is required to maintain actuators.

Dynamic positioning accuracy

Supply pressure is sent to both sides of the piston for stiff, precise actuator operation. Small air volume between the piston and the bottom of the cylinder provides powerful pneumatic stiffness, allowing a high pressure drop – without plug slamming.

Field reversible

Failure mode is easily reversed without additional parts. Reduced inventory costs.

No pressure regulators required

Cylinder actuators easily handle air supplies up to 150 psi (10.3 Bar) with out a pressure regulator and can be operated with as little as 30 psi (2.1 Bar).*

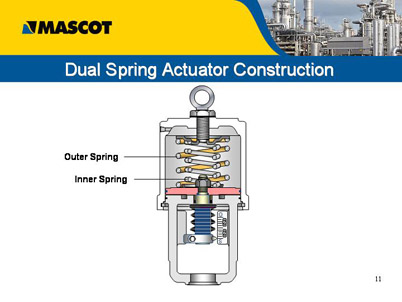

Fail-safe spring

Internal spring provides fail-safe operation in the event of air system failure. Universal spring bench set is not required.

Stiff operation

Supply pressure is sent to both sides of piston for stiff actuator operation.

Durable components

High quality materials require very little maintenance, no diaphragm to rupture.

Simple maintenance

Periodic maintenance is easy to perform, since the spring cylinder actuator only requires the removal of two parts to access all internal parts.

Low air consumption

Cylinder design uses less supply air than comparable diaphragm actuators.

Longer strokes

Size 25 spring cylinder linear actuator has a 1 1 /2 -inch (38 mm) stroke, in contrast to a 3/4 -inch (19 mm) stroke on a comparable linear diaphragm actuator. Larger actuators have similar comparisons. Stroke lengths are available up to 24-inches.

High-level positional stiffness

Small air volume between the piston and the bottom of the cylinder prostiffness vides powerful pneumatic – allowing high pressure, flow over the plug operation without plug slamming.