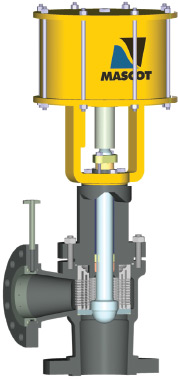

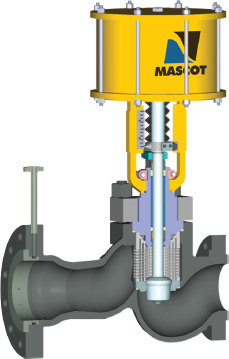

Combined Steam Conditioning Valves (CSCV)

Combined Steam Conditioning Valves (CSCV) offer both pressure reduction and the desuperheating process in a single unit. This application involves injection of cooling water into a highly turbulent zone soon after pressure reduction, resulting in thorough mixing of cooling water with superheated steam. Injected water breaks into infinitely small particles both with the help of pressure and velocity differentials between steam and water. This results in a quick evaporation of injected water.

CSCV’s are particularly popular as they do not have a traditional bypass arrangement and are a compact device in which pressure reduction and desuperheating can take place simultaneously.

Features

- Configuration: Globe inline or angle with expanded outlet where required

- Spray method: Small jets of spray through stainless sleeve at the outlet flange

- Very effective, space and cost saving compared to the conventional Pressure Reducing Desuperheating station (PRDS)

- Sizes available:

- Steam side flange: In accordance with steam pipe sizes

- Water side flange: In accordance with spray water pipe requirements

- Available pressure rating: 150# to 4500#

- Using two CSCV’s, one in operation and one as a standby, can offer uninterrupted automatic operation which is economical and requires less space

- No special trim is needed by using standard Control Valve spares

- Water is sprayed in a way that the CSCV is well protected against pitting and thermal stress / shocks. This is an advantage over other conditioning Valves whereby water is sprayed into a belly of a Valve body

- Efficient up to turndown ratio of 100:1

- The orifice nozzle is specially designed to avoid flashing inside the nozzle

- Advanced seat design for tight shut off

- All internal parts of the Valve can be removed without the Valve having to be dismantled from the pipe